Iyada oo ay sii kordhayaan caanka ah ee madax-goynta awoodda sare leh, waxaan ogaanay in ay jiraan kiisas aad u badan oo ah muraayad difaac ah oo dillaacay. Sababta inta badan waxaa keena wasakhowga muraayadda. Marka tamarta la kordhiyo oo laga dhigo in ka badan 10,000 watts, marka wasakhowga boodhka ahi ku yimaado muraayadda, oo barta gubanaya aan la joojin wakhtiga, tamarta la nuugo isla markiiba way korodhaa, wayna fududahay in la qarxiyo. Dilaaca muraayada ayaa dhibaato wayn u keeni doonta madaxa goynta. Markaa maanta waxaan ka hadli doonaa tillaabooyinka si wax ku ool ah uga hortagi kara muraayadda ilaalinta inay dillaacdo.

Ka ilaali dhibcooyinka gubtay iyo muraayadaha dillaacsan ee muraayadda

Goynta gaaska

Ku saabsan kormeerka dhuumaha:

Kormeerka marinka gaaska wuxuu u qaybsan yahay laba qaybood, mid waa laga soo bilaabo taangiga gaaska ilaa meesha gaaska ee tuubada gaaska, midda kalena waa ka soo baxa gaaska tuubada gaaska ilaa dekedda isku xirka gaaska ee madaxa goynta.

Isbaarada1.Ku dabool xabagta maro cad oo nadiif ah, hawo sii 5-10 daqiiqo, hubi xaalada marada cad, isticmaal muraayad difaac nadiif ah ama galaas, dhig marinka tracheal, hawo cadaadis hoose (5-6 bar) 5-10 daqiiqo, oo hubi in muraayada difaaca uu jiro Biyo iyo saliid.

Isbaarada2Ku dabool marada neefta maro cad oo nadiif ah, hawo sii 5-10 daqiiqo, hubi xaalada marada cad, isticmaal muraayad difaac nadiif ah ama galaas, dhig marinka tracheal, oo hawo cadaadis hoose (5-6 bar) 5-10 daqiiqo (dhamays 20s; joogso) 10s), hubi haddii ay jiraan biyo iyo lenska saliidda haddii uu jiro dubbe hawo.

Fiiro gaar ah:Dhammaan dekedaha ku xidha tracheal waa in ay isticmaalaan isku xidhka tuubooyinka gacmaha ee kaadhka sida ugu badan ee suurtogalka ah, ha u isticmaalin dekedaha degdega ah inta ugu badan ee suurtogalka ah, iskana ilaali isticmaalka dekedaha 90° intii suurtogal ah. Isku day in aad iska ilaaliso isticmaalka cajalada alaabta ceeriin ama xabagta dunta, si aanay u sababin in cajalada alaabta ceeriin ay jebiso ama dunta qashinka xabagta ee dariiqa hawada, taasoo keenta wasakhowga dariiqa hawada si ay u xidho waalka saamiga ama jarista madaxa, taasoo keenta goyn aan deganayn ama xataa jarista muraayada madaxa dilaacdo. Waxaa lagula talinayaa in macaamiishu ku rakibaan shaandhada cadaadiska sare iyo saxnaanta sare (1μm) barta hubinta 1.

Tijaabada pneumatic: ha shidin iftiin, socodsii dhammaan habka daloolinta iyo goynta meel madhan, iyo haddii muraayadda ilaalinaysa ay nadiif tahay.

B.Shuruudaha gaaska:

Nadiifinta gaasta jarista:

| Gaas | daahirnimo |

| Ogsajiin | 99.95% |

| Nitrojiin | 99.999% |

| Hawo cufan | Saliid iyo biyo la’aan |

Fiiro gaar ah:

Goynta gaaska, kaliya gaaska goynta nadiifka ah iyo qalalan ayaa la ogol yahay. Cadaadiska ugu badan ee madaxa laysarka waa 25 bar (2.5 MPa). Tayada gaasku waxay buuxisay ISO 8573-1: shuruudaha 2010; Qaybaha adag-class 2, heerka biyaha 4, heerka saliidda 3

| Darajo | Qaybaha adag (dharka haray) | Biyaha (Dhibaatada Cadaadiska) (℃) | Saliid (Steam/Ceryaan) (mg/m3) | |

| Cufnaanta ugu badan (mg/m3) | Cabbirka ugu badan (μm) | |||

| 1 | 0.1 | 0.1 | -70 | 0.01 |

| 2 | 1 | 1 | -40 | 0.1 |

| 3 | 5 | 5 | -20 | 1 |

| 4 | 8 | 15 | +3 | 5 |

| 5 | 10 | 40 | +7 | 25 |

| 6 | - | - | +10 | - |

C.Goynta shuruudaha dhuumaha gaaska gelinta:

Kahor afuufista: ka hor inta aan la daloolin (qiyaastii 2s), hawada ayaa horay loo sii daayay, waxaana lagu xiray valve saamiga ama jawaab celinta pin 6th ee guddiga IO ayaa ku xiran. Ka dib markii PLC ay la socoto in cadaadiska hawada jarista uu gaaro qiimaha loo dejiyay, habka iftiinka iftiinka iyo daloolinta ayaa la sameyn doonaa. Sii wad afuufi Kadib daloolinta ka dib, hawadu waxay sii wadi doontaa inay soo baxdo oo ay hoos ugu dhacdo booska la socoshada. Inta lagu jiro hawshan, hawadu ma joogsan doonto. Macmiilku waxa uu cadaadiska hawada ka beddeli karaa cadaadiska hawada daloolista una beddelo cadaadiska hawada jarista. U beddel cadaadiska hawada daloolinta inta lagu jiro dhaqdhaqaaqa aan shaqayn, oo ka ilaali gaaska, u gudub barta daloolinta ee xigta; ka dib marka goynta la dhammeeyo, gaasku ma joogsan doono oo kor u qaadi maayo, gaaskuna wuu joogsan doonaa ka dib marka uu jiro dib u dhac 2-3s.

Isku xirka calaamada alaarmiga

A.Xiriirinta alaarmiga PLC

Inta lagu jiro hawlgelinta qalabka, waa lagama maarmaan in la hubiyo in isku xirka calaamadda alaarmiga uu sax yahay

- Interface-ka PLC ayaa marka hore hubinaya mudnaanta alaarmiga (labaad oo kaliya joogsiga degdega ah) iyo habaynta ficilka daba gal ee alaarmiga ka dib (joojinta iftiinka, joojinta ficilka).

- Ma jiro kormeer iftiin ah: soo saar khaanadda muraayadda ilaalinta hoose wax yar, LED4 alaarmiga ayaa soo muuqda, haddii PLC ay leedahay gelinta alaarmiga iyo ficillada xiga, haddii laysarka uu gooyo signalka LaserON ama uu hoos u dhigo tamarta sare si loo joojiyo laysarka.

- Kormeerka iftiiminaya: Ka saar calaamada alaarmiga pin 9-aad ee boodhka IO ee cagaaran, iyo haddii PLC ay hayso macluumaadka alaarmiga, hubi in laysarka uu hoos u dhigi doono danab sare oo uu joojinayo iftiiminta.

Haddii OEM ay heshay calaamadda alaarmiga, mudnaanta ayaa ku xigta oo keliya joogsiga degdegga ah (kanaalka gudbinta degdegga ah), signalka PLC si dhakhso ah ayuu uga jawaabaa, iftiinkana waa la joojin karaa wakhtiga, iyo sababaha kale waa la hubin karaa. Macaamiisha qaar ayaa isticmaala nidaamka Baichu mana helin digniinta digniinta. Isku xirka alaarmiga wuxuu u baahan yahay in la habeeyo oo dejiyo ficilka dabagalka (iftiin joojinta, ficil joojinta).

Tusaale ahaan:

Hababka qaylo dhaanta hab-qabsiga

B.Isku xirka korantada ee muraayada indhaha

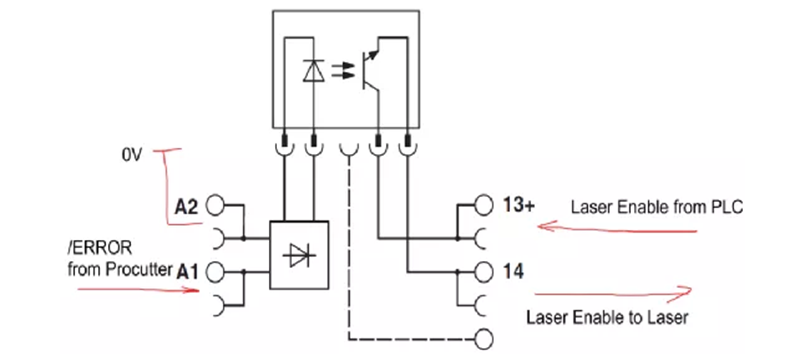

Haddii PLC aysan isticmaalin kanaalka gudbinta degdega ah, waxaa jirta suurtagal kale oo ah in leysarka lagu dami karo waqti gaaban. Calaamadaha digniinta madaxa goynta waxay si toos ah ugu xidhan tahay isu-gudbinta optocoupler si loo xakameeyo calaamadda LaserON (aragti ahaan, isku-xidhka badbaadada laysarka ayaa sidoo kale la xakameyn karaa), iftiinka si toos ah ayaa loo gooyaa ( awood laysarka ayaa sidoo kale loo dejiyay inuu hooseeyo -> laser off). Si kastaba ha noqotee, waxaa lagama maarmaan ah in lagu xiro calaamadda alaarmiga ee Pin9 ee PLC si isku mid ah, haddii kale goynta madaxa digniinta, macaamiishu ma garanayo sababta, laakiin laysarka ayaa si lama filaan ah u istaagaya.

Isku xirka aaladaha korantada ee isku xiran ee opto-ku-xirnaanta (alaarmiga-qalabka korantada-laser-ka-isku-xidhan ee alaarmiga)

Dhanka heerkulka heerkulka, tani waxay u baahan tahay in la tijaabiyo oo ay dejiso OEM iyadoo loo eegayo xaaladda goynta dhabta ah. Biinanka 6-aad ee guddiga IO wuxuu soo saaraa qiimaha la socodka heerkulka muraayadda ilaalinta (0-20mA), heerkulka u dhigmana waa 0-100 darajo. Haddii OEM ay rabto inay sameyso, way sameyn kartaa.

Isticmaal muraayadaha ilaalinta asalka ah

Isticmaalka muraayadaha ilaalinta ee aan asalka ahayn waxay sababi karaan dhibaatooyin badan, gaar ahaan madaxa jarista 10,000-watt.

Dahaarka muraayadda liidata ama walxaha liita waxay si fudud u sababi karaan heerkulka muraayadda inuu si dhakhso ah u kaco ama buskugu noqdo mid kulul, gooyntuna waa mid aan degganayn. Xaaladaha daran, muraayadda ayaa qarxi karta;

2. Dhumucda aan ku filnayn ama qaladka cabbirka cidhifka ayaa sababi doona daadinta hawada (alaarmiga cadaadiska hawada ee godka), wasakheeya muraayadda ilaalinta ee moduleka diiradda, taasoo keentay goynta aan degganeyn, goynta aan la dabooli karin, iyo wasakhowga halista ah ee muraayadda diiradda;

3. Nadaafadda muraayadda cusub kuma filna, taasoo keenta gubasho joogto ah oo muraayadda ah, wasakhowga muraayadda ilaalinta ee qaybta diiradda, iyo qarax lens oo halis ah.

Waqtiga boostada: Agoosto-25-2021